Plastic box inserts

If you need to improve the efficiency of your handling, transport or storage, adding container inserts to your tote boxes or returnable packaging can make a significant difference.

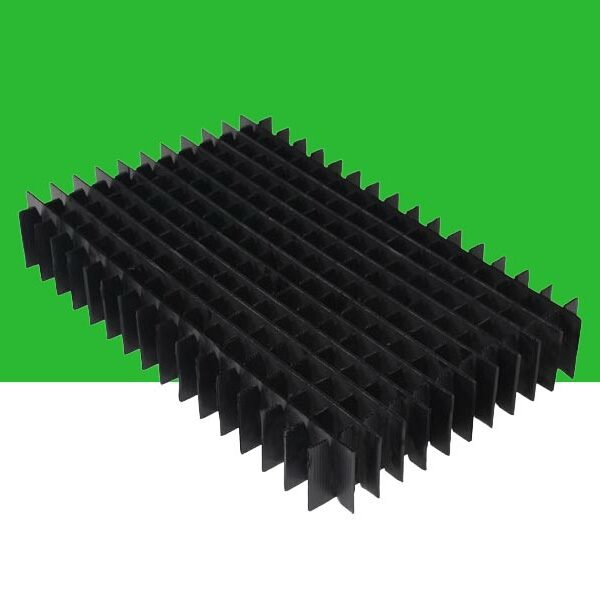

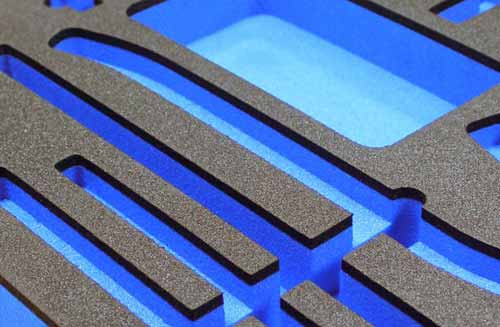

Container inserts, including divider sets, foam, and moulded plastic trays, help to improve the efficiency and protection of returnable transit packaging. Typically used in Euro containers and tote boxes, plastic box inserts can reduce damage by preventing the movement of parts within the outer container. They can also increase staff productivity through quicker packing and unpacking, whilst higher part density also improves transport efficiency.

At GWP Correx®, we have been manufacturing plastic insert packaging for more than 25 years. Our expert team and manufacturing capability allow us to tailor your dunnage and inserts precisely to your application.

Our container insert options

Benefits of container inserts

By working with us at GWP Correx® to source container inserts, you can benefit from:

What our customers say...

We previously used cardboard but needed something more robust and with better performance around water. Lead time and price were both excellent. The team and service was quick, reliable, helpful and friendly.

Danielle Roach | Latis Scientific

We have stayed with GWP because the service is so good. The team is friendly, hold the items needed in stock and the pricing is competitive. We buy thousands of boxes each year, plus foam and division sets.

John Wayman | Managing Director | Bondline

GWP really helped us out. They quickly came up with a simple but very effective Correx solution. We’re very pleased with the outcome and we had quite a fun and successful team building hour putting them all together!

Paul Wilson | Project Manager | Heathrow Terminal 2

FAQs

What types of container inserts are available?

There are four main types of container inserts available. These are Correx®-based inserts, including division sets, layer pads, custom-designed items, moulded plastic and vacuum-formed inserts, foam dunnage, and single-trip options such as corrugated cardboard inserts.

Can plastic box inserts help improve staff productivity?

Reusable plastic box inserts, such as Correx® dividers, foam inserts, and even layer pads, can significantly impact your business’s productivity and efficiency. It allows multiple items to be transported more easily in a single container, maximising available space, and also aids packing and unpacking processes.

Can container inserts help prevent damage during handling?

By minimising the movement of parts within the outer container, inserts, and dividers can significantly reduce damage caused by mishandling. However, foam or Bubble board dividers can provide extra protection for especially sensitive or delicate parts, including those with specialist surface finishes, that may get scuffed or scratched.

Is it best to source outer containers and inserts together?

Sourcing your handling containers and appropriate inserts together can provide several benefits. Advantages include lower costs, shorter lead times, reduced admin and ordering processes, and – crucially – improved compatibility and fit. However, GWP can create inserts for containers you may have already purchased from other sources.

Are container inserts suitable for static-sensitive items?

If you are in the electronics industry or manufacture parts or equipment that heavily utilise PCBs or other similar items, you will be well aware of the potential damage caused by static charges. Your inserts and dividers can help with this, with options for a wide range of ESD-safe foams and conductive materials (including Corstat® and Corriplast).

Guides, articles and further reading:

Why work with GWP Correx®?

So why should your business trust us with your container inserts and other crucial supply chain packaging?

Well, for starters, GWP Correx® have more than 25 years of experience supplying a vast range of manual handling and returnable packaging products.

As well as working alongside the largest independent converter of Correx®, your business can also benefit from the broadest range of container inserts, dunnage and returnable packaging from a single supplier.

For any custom requirements, our team of Correx®-specific designers will be on hand to guide and advise you at every stage of the design process.

Besides this, sourcing your outer totes and containers alongside any inserts and dividers also ensures much greater compatibility – and therefore improved efficiency, protection, and costs.

And finally, all of this is coupled with a genuine focus on customer service, including a dedicated account manager offering detailed knowledge of the product you require and the challenges your industry faces.

Disclaimer: Application images on this page may have been enhanced or created specifically to illustrate a products features and/or potential uses. Please see our content policy for further details.

Quotes, technical info and advice

Speak with our UK-based Correx® experts

The information on this page has been collated, checked and approved by several of our Correx® packaging experts: